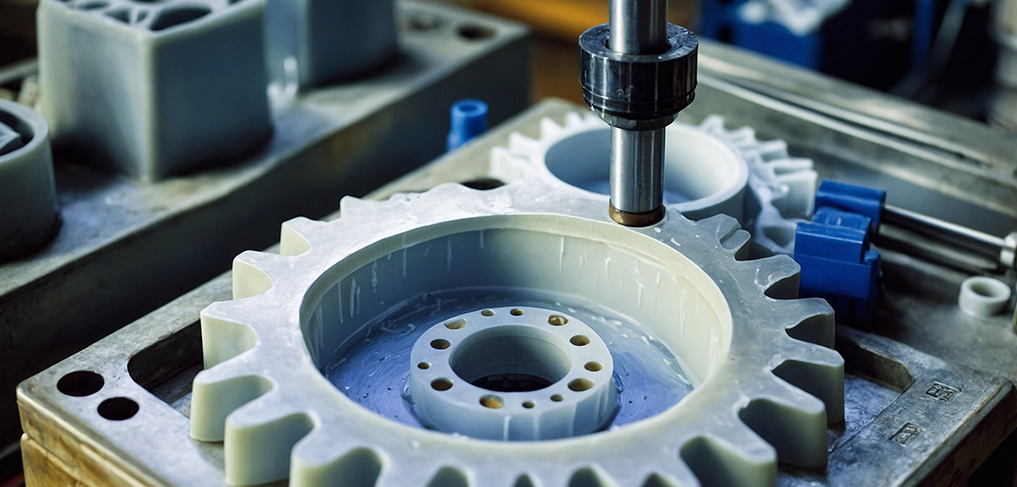

Vacuum casting is a cutting-edge technique used for producing prototypes and small series of plastic or metal parts by utilizing vacuum technology. In this process, a liquid material is poured into a silicone mold, and air is removed from the mold, allowing the object to take on the desired shape and quality.

The process begins with the creation of a silicone mold, made using 3D printing to produce a master model. The mold is then used to cast materials while the vacuum eliminates trapped air, preventing bubbles and surface defects, thus enhancing the precision of the final piece.

Vacuum casting excels at finely reproducing details, making it ideal for low-volume production runs where tight tolerances are required. With the growing availability of 3D printing, this technology is becoming an increasingly common solution for rapid prototyping, providing the flexibility to meet the specific needs of each project.

Industries that particularly benefit from this technique include automotive, aerospace, and medical fields, where high-quality prototype finishes are essential.

To further enhance the efficiency of vacuum casting, Vuototecnica offers a comprehensive range of components for vacuum generation and management, including pumps, filters, and valves. For more information on available solutions, visit www.vuototecnica.net.