The consequences of the war had a strong impact on energy supplies, but the side effects are also other: the packaging sector had to face a 20-50% increase in the price of paper and cardboard.

With these assumptions, the increase in production costs was about 25-30% with particular attention to the choice of materials for packaging.

Environmental sustainability was the first reason that led several companies to choose paper rather than plastic; consumers willingly accepted. For the past two to three months, however, the price of paper has risen by more than 40%. Paper mills delayed in some deliveries, and maximum supply quotas were set for individual customers and States.

Packaging manufacturers wonder how to get by with these price increases and sourcing difficulties.

Investing in technology has always proved to be a winning strategy, in every crisis we’ve had to face since the 2000s. This is why Vuototecnica supports its clients in making conscious and effective choices, capable of greatly lowering costs due to unnecessary downtime.

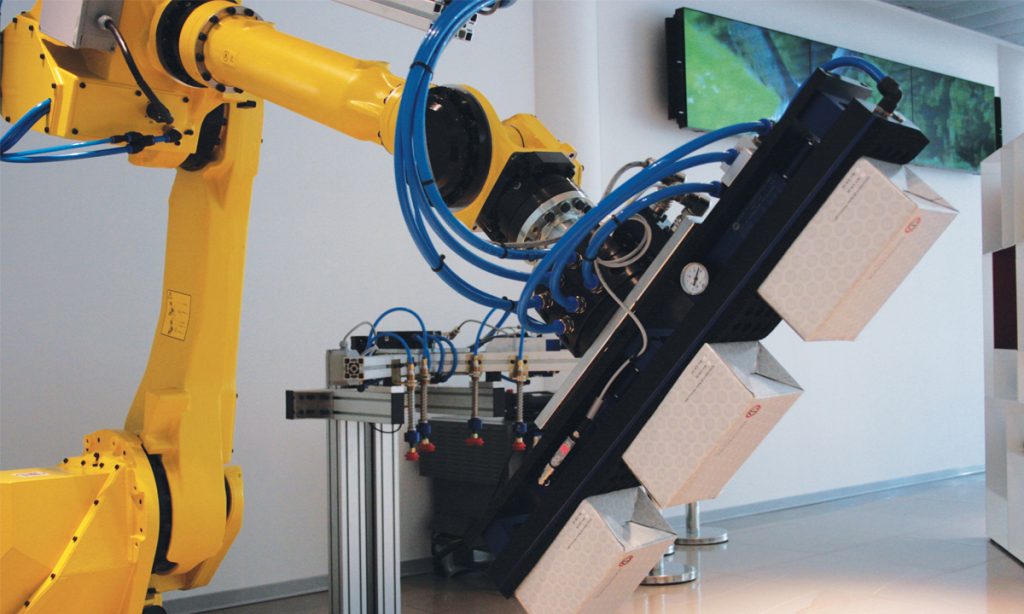

During packaging, thanks to vacuum and Vuototecnica solutions, packages are not damaged and it is not necessary, during product handling and pallet creation, to change the format of the robot gripping hands.

Vuototecnica gripping and vacuum generation solutions are so versatile that they can manage several products and packages at the same time.

To learn more about Vuototecnica products: www.vuototecnica.net