In the industrial and mechanical sectors, technical terms might seem far removed from daily life. Yet, many of the principles they describe are applicable in surprisingly ordinary situations. For instance, vacuum ejectors, also known as Venturi devices or vacuum generators, play a vital role in various industrial operations and operate on an intriguing principle that can also be observed during a car ride.

Imagine lighting a cigarette (or, for non-smokers, holding an incense stick) while driving with the window slightly open. You’ll notice the smoke being drawn out of the cabin. This occurs due to the Venturi effect: the fast-moving air outside lowers the pressure near the window opening, creating a vacuum that pulls out the smoke.

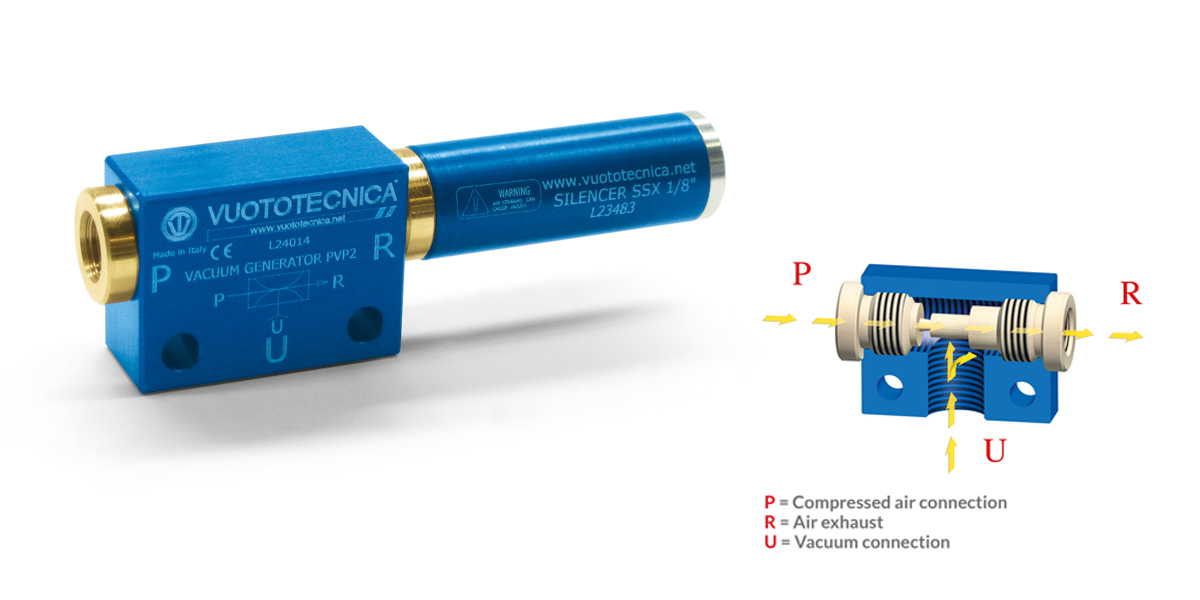

Vacuum ejectors exploit this concept to create a vacuum using compressed air or fluids. Unlike conventional vacuum pumps, which rely on mechanical components powered by electric motors, ejectors utilize fluid dynamics. This gives the device simplicity and reliability, due to the lack of moving parts, reducing the need for maintenance and extending its lifespan.

Companies typically specialize in producing either Venturi systems or vacuum pumps, with few offering both solutions. These technologies are often pitted against each other in the market, in an effort to highlight the advantages of each. However, both systems provide effective vacuum generation solutions, with the final choice depending on the specific application’s requirements, necessary performance, and costs.

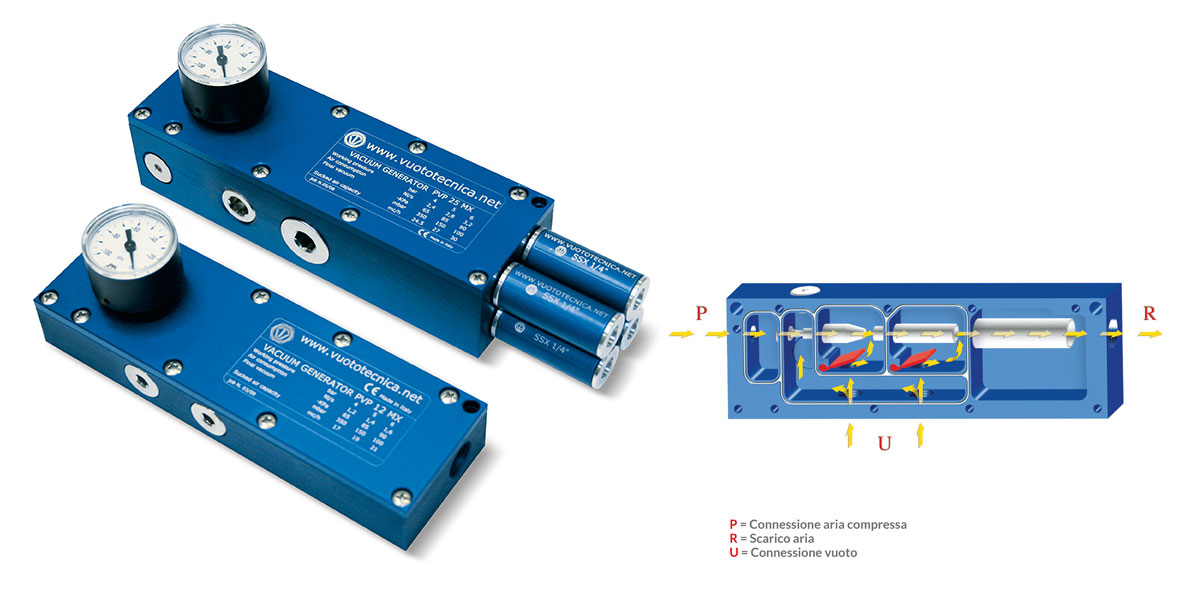

Ejectors are available in single-stage and multi-stage models. The former are simpler and suitable for situations requiring quick action, though they are less efficient in terms of air consumption. The latter, more complex, offer remarkable efficiency by optimizing the use of compressed air and producing a stronger vacuum flow.

Choosing between a single-stage or multi-stage ejector depends on the specific needs of the application, balancing the speed of response with energy efficiency.

The industrial applications for vacuum ejectors are diverse, ranging from handling delicate items to creating controlled environments in manufacturing processes. However, it’s essential to carefully consider the context in which these devices are used.

By thoroughly analyzing the operational cycle, vacuum needs, and energy efficiency, it’s possible to steer towards the most sustainable and cost-effective solution, determining whether a single-stage ejector, a multi-stage ejector, or a vacuum pump is more suitable.

So, the next time you see smoke swiftly exiting the window of a moving car, think of vacuum ejectors. Based on an intuitive physical principle, these devices play a crucial role in numerous industrial processes, showing how everyday observations can inspire the development of technological innovations. For more information, visit www.vuototecnica.net.