In challenging measurement situations, simple technologies can often provide solutions, like in a Chinese thermal power plant.

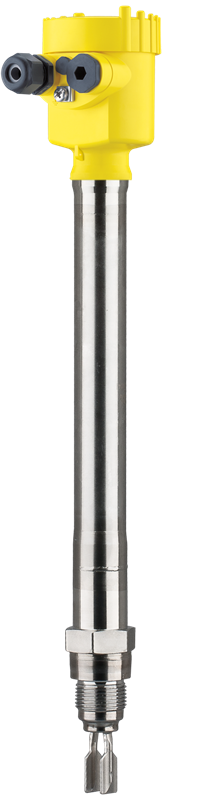

The vibrating level switch VEGASWING 66 proved to be robust enough to handle a demanding environment and effectively simplified the level measuring point, which had previously been considered overly complicated.

The Chinese thermal power plant operates at a capacity of 380 MW and uses a high-pressure steam bypass system, mainly during turbine startup. When the turbine starts, the boiler generates steam, but its parameters are not yet suitable for the turbine’s operating state.

The steam contains excess moisture and has a lower temperature, which could potentially damage the turbine blades with fine water droplets at high speed. To prevent this, the steam is first directed through a bypass system until it reaches the correct condition – without water droplets and at the required operating temperature. Only then is the system switched off, and the steam is fed into the turbine.

During the use of the steam bypass system, water accumulates at the bottom of the pipe. Timely drainage of this water is essential to avoid flooding and problematic situations. Therefore, accurate water level measurement and controlled lowering are necessary. Previously, a float switch was used to detect the water in the turbine’s steam bypass system, but it caused frequent error signals, leading to system shutdowns.

To address this issue, the plant operator sought a reliable level switch capable of functioning at high temperatures (up to 325.5° C) and high pressures (38 bar). The VEGASWING 66 level switch proved to be the suitable and dependable solution for their needs.

Inductive drive as a solution for measurement under extreme temperatures

Inductive drive technology emerges as the ideal solution for measuring under extreme temperatures in challenging process conditions. While vibrating, level switches are valued for their simplicity and robustness, they faced limitations when exposed to temperatures above 280° C or extremely low temperatures. This was due to their drive mechanism, which relies on technology, not being suitable for such extreme conditions.

However, the introduction of VEGASWING 66 revolutionized the field with its innovative inductive drive. Unlike the traditional piezo-based drives, the patented inductive drive of VEGASWING 66 effortlessly excites the tuning fork even in the most extreme temperature settings.

As a result, users can enjoy the ease of installation and handling characteristic of vibrating level switches while benefiting from an extended temperature range of -196° to +450° C and a pressure range of -1 to +160 bar. This made the VEGASWING 66 sensor the perfect choice for level detection in the steam bypass pipe.

The sensor offers an additional advantage by continuously monitoring itself. Users can initiate a function test at any time to ensure the sensor is in optimal working condition. For example, if corrosion on the fork is detected, it will be promptly reported. Conducting the function test is as simple as pressing a button.

Moreover, the VEGASWING 66 sensor holds SIL2 qualification, allowing its use in homogeneously redundant systems up to SIL3, providing an extra layer of safety and reliability.

Level switch for extreme process conditions | VEGASWING 66

Now equipped with the VEGASWING 66 vibrating level switch, the measuring point successfully overcame another challenge: dealing with high-speed moist steam flowing through the pipe. To address this issue, special attention was given to the positioning of the stainless steel tuning fork inside the pipe.

The solution involved using a slightly longer mounting socket, which was installed at the measuring point. This adjustment moved the tuning fork further back, keeping it out of the path of the fast-flowing steam and ensuring its protection.

Since implementing this modification a year ago, the VEGASWING 66 by VEGA has been fulfilling its role reliably and continuously without any interruptions, much to the satisfaction of the plant operator.

The switch’s performance has been consistent, and it has proven itself to be a dependable and effective solution for level detection in the challenging environment of the steam bypass pipe.

Visit the VEGA website to read more!