CAP IT thermowell serves as a protection for the temperature sensor, allowing temperature measurement without direct contact with potentially harmful process conditions. These conditions may include corrosive fluids, high pressures and velocities, as well as exposure to direct flames. This significantly prolongs the lifespan of the sensor and enables maintenance without interrupting the operation of the system.

Thermowells can be made of various metal alloys, depending on the specific process conditions. The most commonly used alloys are stainless steel (AISI 304, AISI 316/316L, AISI 310, AISI 446, …) and Inconel (600, 601), but other special alloys such as Monel and Hastelloy can also be used.

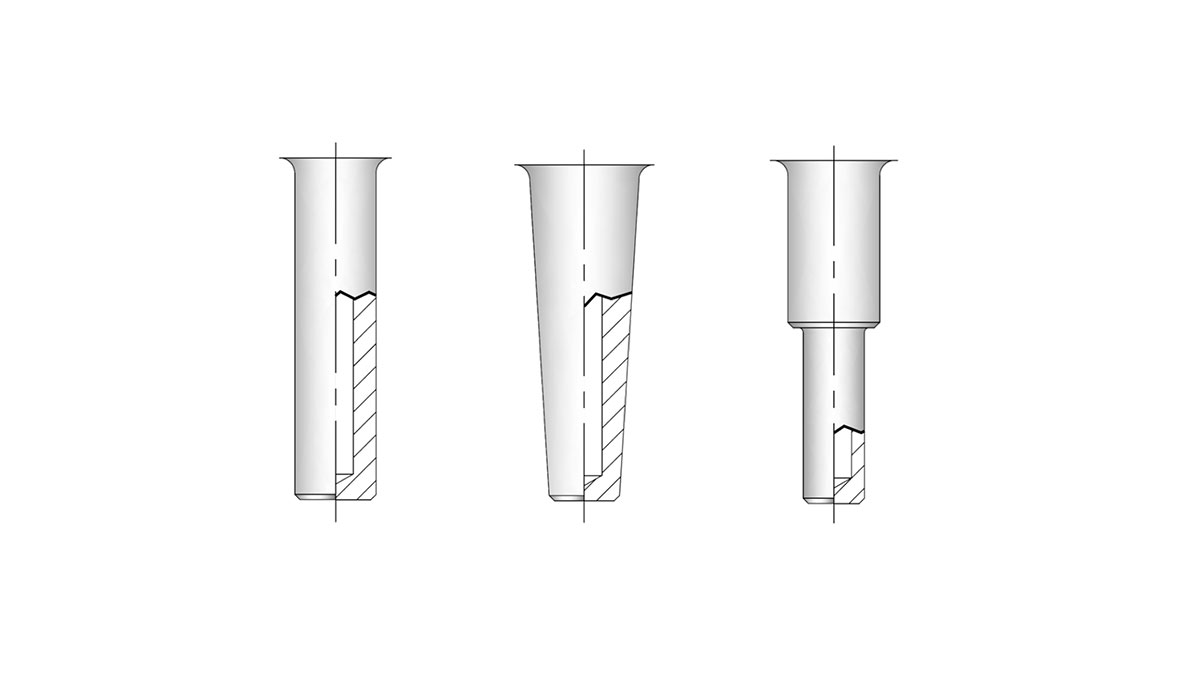

Based on the construction method, thermowells can be categorized into two types: those made from tubes and those made from solid bars. The latter can be further divided based on the profile of the stem immersed in the process.

Therefore, the following types of thermowells can be identified:

- Thermowells with a cylindrical or straight profile;

- Thermowells with a conical profile;

- Thermowells with a stepped or tapered profile;

Thermowells, whether made from tubes or solid bars, can be connected to the system using various types of process attachments. The most common types include:

- Threaded attachment: NPT, Gas, Metric, etc. This involves threading the thermowell directly into the process;

- Sliding threaded fitting: this type of attachment is often used with tool of medium/small diameters. It consists of a threaded fitting that can slide onto the thermowell to facilitate installation;

- Flanged attachment: the thermowell is connected to the system using a flange, providing a robust and secure connection;

- Sliding flange: this type of attachment features a flange that can be moved along the thermowell to facilitate installation;

- Welding attachment: in this case, the thermowell is directly welded to the system without the use of threaded or flanged parts;

These different types of attachments allow for the adaptation of the thermowell to the specific needs of the system and process.

Visit the CAP IT website to learn more!