Researchers at MIT Lincoln Laboratory have developed an innovative method for 3D glass printing at low temperatures and high performance, resulting in a material with unique electrical, optical and chemical properties.

Reduction of temperature

This is not the first case of 3D printing experimentation for glass, but the system devised by the Lincoln scientists involves a clear reduction in the temperature required for the process.

The post-processing of glass usually involves exposure to temperatures close to 1000°C to produce an inorganic material. The MIT method, on the other hand, involves the layering of a custom ink, which is curable at 250°C.

The advantages of 3D printing

In the article “Low Temperature Additive Manufacturing of Glass“, the team highlighted how emerging techniques for the additive generation of inorganic structures have the potential to revolutionize the ceramic and glass industries. In fact, glass offers important advantages through 3D printing, such as better biocompatibility and greater thermal stability.

Focus on the nanomaterial

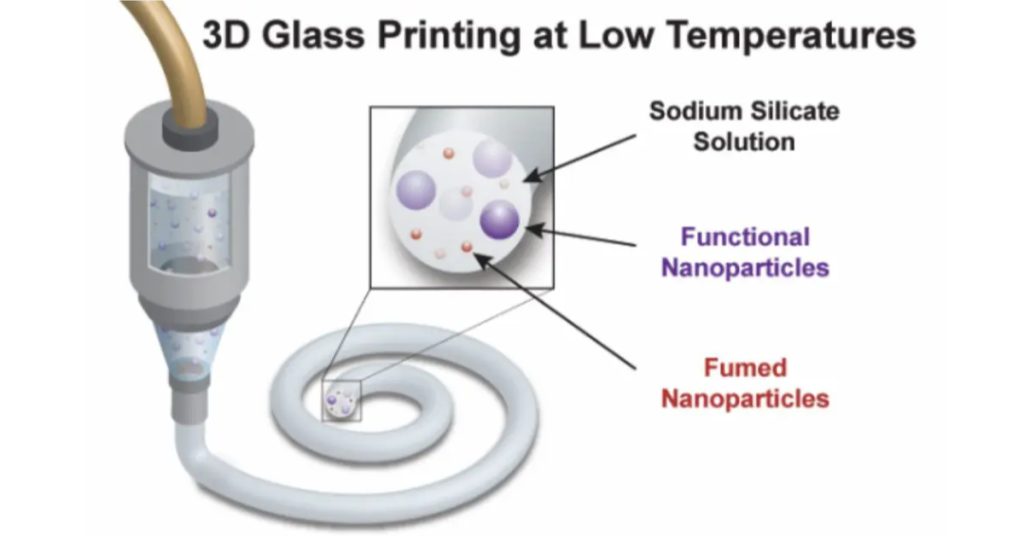

The system developed by the researchers made it possible to eliminate the problem of high temperatures. The conclusion is in the nanomaterial used: a sodium silicate solution, incorporated into functional nanoparticles and smoked silica nanoparticles to increase solubility. The combination of these three elements allows to carry out molding at low temperatures and to obtain a variety of materials, characterized by multiple characteristics. The material also showed greater stability and strength through the addition of a mineral oil bath to the polymerization process.

Unlimited solutions and applications

Scientists have proposed a modular system that can be tuned to print a wide variety of inorganic glasses with embedded functional nanomaterials (dielectrics, metallic and optical). This versatile material platform, when combined with multi-material additive manufacturing, will enable the fabrication of a wide variety of robust microsystems.

It is a simple technique that optimizes the 3D glass printing process, giving it a multitude of applications. The possibilities are almost endless: in fact, it will be possible to create high-performance glass surfaces or even glass capable of reacting to the environment, through shape-memory materials.

Source: rinnovabili.it

Cover image credit: Steven Keating | MIT – CC BY-NC-ND 3.0 DEED