3D printing can foster profound change in architecture and construction. In addition to this cutting-edge technology, which guarantees new production processes and alternative forms, attention must be paid to materials aimed at containing the environmental impact.

Research in progress

The construction sector currently produces 35% of all landfill waste globally. And the hunger for cement does not cease, despite the fact that the consequences of the massive use of this material are now known. However, new research suggests a possible solution, thanks to the use of a perhaps unusual component for the production of 3D printed concrete: recycled glass.

Stimulate recycling

Concrete is made up of a mixture of cement, water and other aggregates (such as sand). And the glass replaces this last ‘ingredient’ in the mix. It is, in fact, easy to recycle and it can be used to produce concrete, without any complex processing. In light of this, the enormous push that the construction sector could transmit to the glass recycling system should not be overlooked.

The processing

To verify the feasibility of the proposal, the researchers used soda-lime beverage glass, obtained from a recycling company. The bottles were first crushed by means of a crushing machine. The pieces obtained were then washed, dried, milled and sieved, until particles smaller than a square millimeter were obtained.

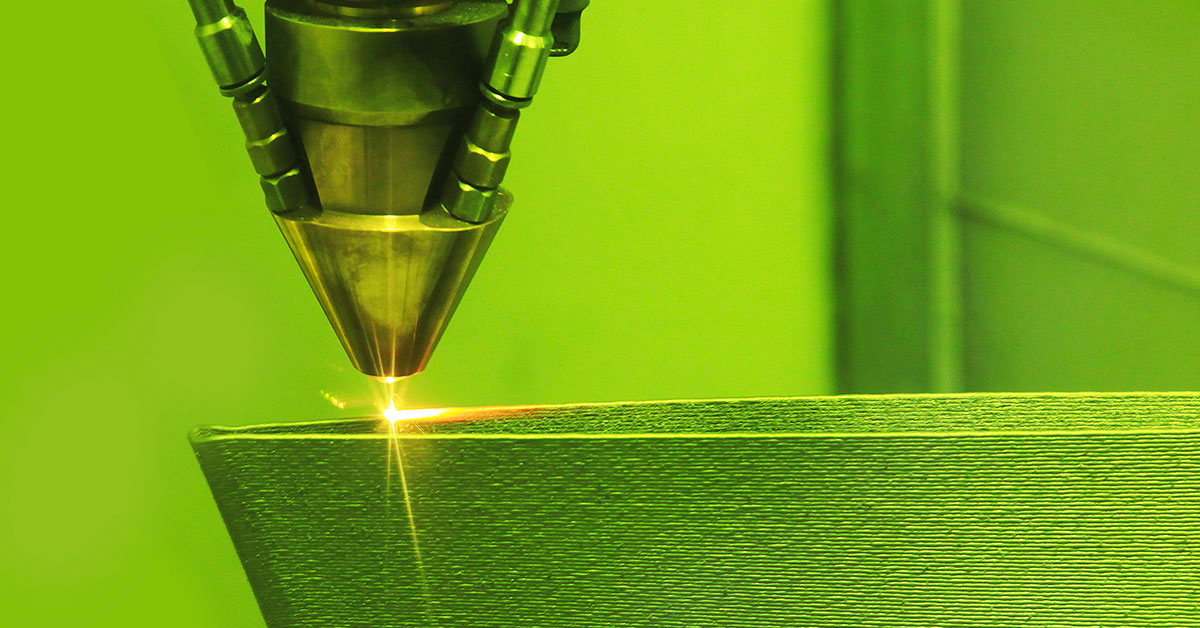

The potential of 3D printing

The product of these processes, comparable to sand, is used to obtain concrete. The 3D printing of this material allows the creation of prefabricated wall elements and blocks, whose assembly favors the manufacture of buildings according to updated times and shapes. This procedure therefore gives new life to the discarded glass and strongly limits waste and the related pollution.

The choice of glass

But the contribution of glass does not end with sustainable data. In fact, it contributes to the development of a concrete with superior properties compared to that containing natural sand.

Concrete made with soda-lime glass has better insulating properties, thanks to a thermal conductivity that is three times lower than that of traditionally used materials. This feature can significantly reduce the costs required for cooling and heating the building.

Key word: progress

The 3D printing system has the ability to work 24 /7, reduce the amount of waste and increase the safety of construction works.

Grasping the potential of glass in the development of this technology means recognizing the material a profound renewal value for the sustainable progress of our cities and homes.

Source: theconversation.com