Automation and digitalization are contributing to significantly change the glass sector, influencing both production processes and finished products.

In order to respond to climate policies and correctly organize the disposal and demolition of waste, it is in fact necessary to collect and evaluate as much data as possible. And it is in this context that track and trace comes into play.

To identify products and processes

The track and trace process begins when the company receives an order. This method makes it possible to organize and optimize the production phases, tracing both products and processes throughout the entire life cycle.

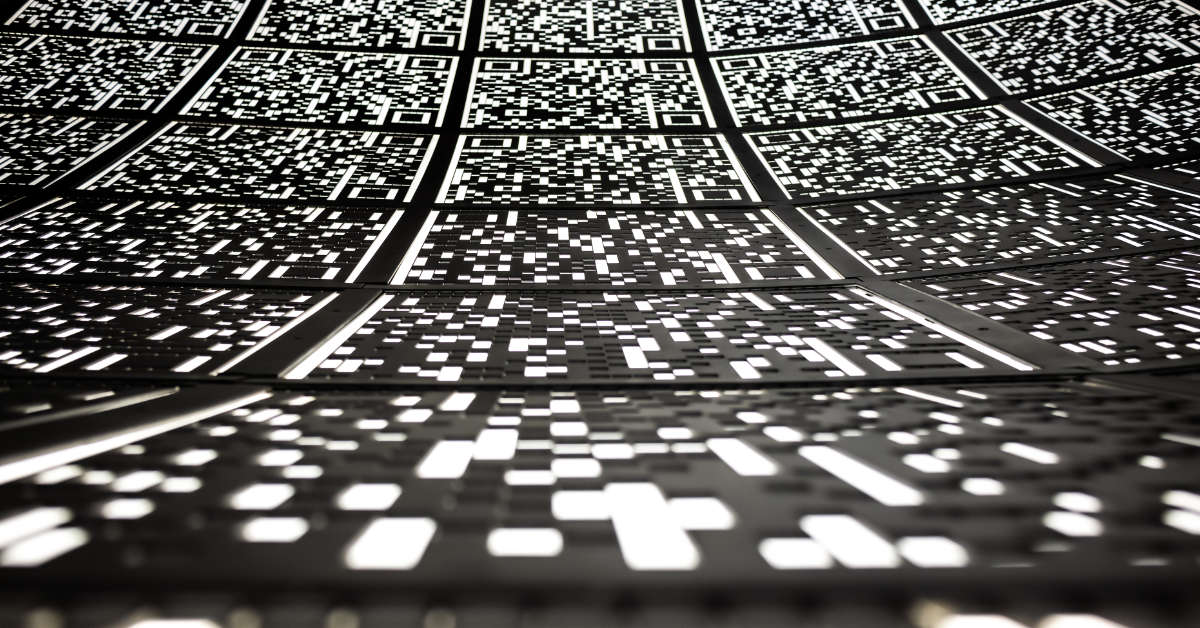

A virtual ID is created and printed on the glass plate during production planning. It is a data matrix code, which identifies the pieces and is constantly updated, providing a complete overview of the processes carried out on the product.

Loyalty and sustainability

The track and trace allows you to intervene promptly in the event of accidents and to rebuild damaged glass just as quickly. It is also possible to record any information on the pane both for a possible replacement and for its reuse or recycling. This solution is therefore strategic for improving the production processes and the company’s environmental footprint.

This approach promotes brand reliability and greater confidence in the consumer, who can enjoy transparent information about the supply chain. A detail that, according to an MIT study, can translate into a 2-10% increase in willingness to pay.

Integration with the production system

The major advantage is that the system can be integrated into an existing production environment. And to extend beyond the factory itself. It can in fact end either in an interface with the customers’ production management system or in a cloud application that end consumers can use.

Distributed and transparent accounting

These considerations imply the need for increasing attention to the security and immutability of data, in other words for blockchain technology. The blockchain is used for applications in product lifecycle management. It is an extremely attractive technology for the industrial sector, since it is by definition a shared and immutable ledger, which facilitates the process of recording transactions and tracking assets in a business network.

The blockchain is not limited to storing data on a single server, but duplicates them in several parts of the world, thus presenting itself as a distributed ledger technology.

We are therefore moving towards an era of production in which the transparency and traceability of processes, products and transactions will determine the competitiveness of companies.

Source: glass-international.com